JUNE 2024

New Bicycle Racks

Due to the increasing use of bicycles by the company’s employees, a bike storage solution was created on the company premises in May/June 2024. This storage area was also equipped with power outlets so that employees can charge their e-bike batteries during work hours.

APRIL 2024

Membership with Jobrad

Burkhardt GmbH Maschinen- und Metallbau is now a member of the bicycle leasing provider, JOBRAD! This allows every employee the opportunity to lease a bicycle through JOBRAD and benefit from the advantages in payroll. The first three bicycles have already been leased by employees!

24 January 2024

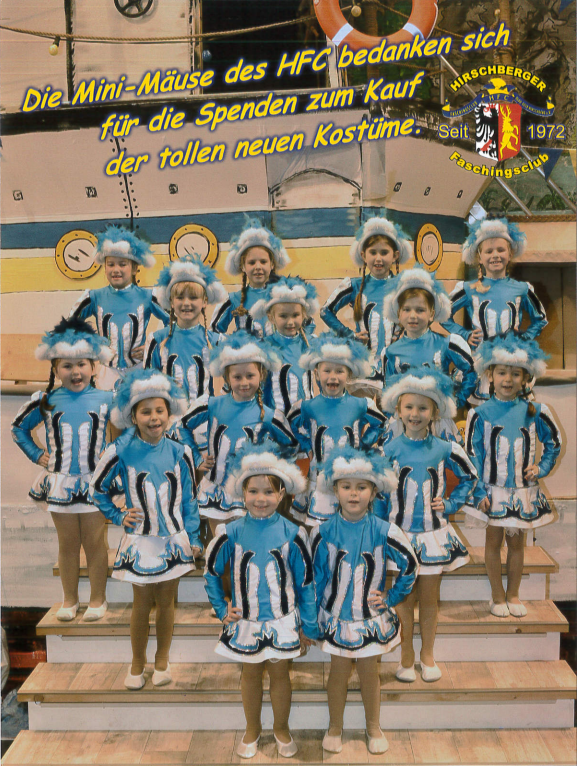

Support for the Hirschberg carnival club

Burkhardt GmbH Maschinen- und Metallbau supports the youngest members of the Hirschberg carnival club with a donation for new costumes.

24 January 2024

Apprenticeship examination

Our apprentice Sebastian Karl is now a permanent member of our team after completing his 3.5-year apprenticeship and successfully passing his journeyman’s examination.

We are proud that he has completed his training with us and look forward to continuing to support his professional development.

08 December 2023

Christmas celebration

This year’s Christmas party took place on December 8, 2023. It started at lunchtime with a cozy barbecue, where we could look back on the year.

We then went bowling in the afternoon. We were able to put our skills to the test in a cheerful atmosphere and compete in friendly competition.

The evening then took us to a restaurant, where we enjoyed the festive atmosphere and good company.

01 September 2023

New apprentices

On September 1, 2023, we welcomed two apprentices, Michael Karl and Le Ngo Viet An.

They have started their apprenticeship as precision mechanics.

We wish them much success and fun in their training.

31 July 2023

New ETA pellet heating system

Burkhardt GmbH Maschinen- und Metallbau now heats with the sustainable fuel wood pellets.

In spring 2023, the 25-year-old oil heating system was removed and replaced with a new environmentally friendly ETA pellet heating system. The new heating system has an output of 105 kW and up to 11 tonnes of pellets can be stored in the storage tank.

We would like to thank the company FREY Haustechnik GmbH & Co. KG from Saalburg-Ebersdorf for the installation of the ETA pellet heating system.

16 February 2023

Award for sustainable business practices

We receive a certificate for our participation in the network for sustainable management in terms of the Thuringia Sustainability Agreement.

This is the third time we have participated in this agreement.

14 January 2023

Job fair in Zeulenroda

We were present at the job fair of the East Thuringia Chamber of Industry and Commerce at the Friedrich-Solle-Regelschule in Zeulenroda. We provided information about our training offers and employment opportunities.

The fair was very well attended, we had a lot of traffic.

07 July 2022

100 years FSV Hirschberg

Burkhardt GmbH Maschinen- und Metallbau congratulates FSV Hirschberg on its 100th anniversary. As a donation on the occasion of this event a beer barrel was gifted.

30 March 2022

New website

The new website of Burkhardt GmbH Maschinen- und Metallbau goes online!

23 March 2022

Pupils visit from Regelschule in Hirschberg / Saale

On March 23 2022, students of the 9th grade of the Regelschule in Hirschberg, together with their teacher Mrs. Saupe, visited Burkhardt GmbH Maschinen- und Metallbau to get an idea of the company and the work around the material metal.

The students received practical demonstrations on the machine tools in the workshop and theoretical information about the company, its products and possible future training.

For years, there has been close cooperation between Regelschule Hirschberg and Burkhardt GmbH Maschinen- und Metallbau. Every year, students have the opportunity to get to know the company through excursions and to learn more about working in the metal trade through student internships or holiday jobs.

H. Ruck

Burkhardt GmbH Maschinen- und Metallbau is also a member of the support association of Regelschule Hirschberg.

December 2021

Plasma Cutter

In December 2021 a new plasma cutter was purchased. This makes it possible to react flexibly and quickly to the wishes of our customers.

The plasma cutter works with computer-controlled manufacturing software. Direct communication between the CAD workstation and the plasma cutter is possible.

technical specifications

- cutting of high quality metal parts

- for structural steel and stainless steel

- up to a sheet thickness of 25 mm

- maximum cutting area: 1250 mm x 2500 mm